Modernization of Eastern Europe Glass Plants

In the expanding market of vacuum systems for glass production, many OEMs respond strategically through competitive pricing and technological novelty. But when the fundamental question of an installation’s Life Cycle Cost is considered, Pneumofore maintains a firm, leading position.

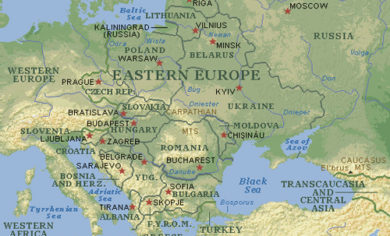

Customers choose Pneumofore systems as the result of long-term analysis of new investments with a focus on high durability, productivity, and efficiency. The question of spending more on higher technology is answered positively in the vast majority of cases. Especially in Eastern European countries, one finds a rapidly growing trend to execute a full analysis of an investment, right down to the maximum cost increase of spare parts over ten years and warranty extensions up to five years.

Vacuum systems require more specifications for long-term equipment performance, availability and cost of maintenance than for the initial purchasing price. With the rising cost of electrical power and water, operating costs generate by far the largest share of the equipment’s entire Life Cycle Cost. In the case of a state-of-the-art glass plant, top performance over ten to twenty years thanks to high efficiency is quickly becoming the customer’s main interest.

The number of Pneumofore UV vacuum systems in Eastern Europe is growing considerably, thanks in great part to the expertise of our local partners. Through the Kiev-based Ukrainian distributor Compressors International alone, Pneumofore has established numerous references: Sklo-Zorya Saint Gobain, Gostomel, Kostopol, Rokinoe glass factories. These glass plants and others worldwide represent a new reality that offers challenging and attractive opportunities for the traditionally-minded Western European business community.