Vacuum for Misr Glass Manufacturing in Egypt

The Glassman Show in Cairo early September 2007 offered Pneumofore the opportunity to visit MGM nearby the capital city of Egypt. We were impressed by the competence of the technical team and the importance given to the vacuum system, which strongly contributes to determine the quality and production speed of the glass containers.

Piping and accessories are installed according to Pneumofore instructions, the UV units are kept clean and serviced regularly. This professional approach of MGM results from an important learning process, since the large price difference of pumps manufactured by various European companies initially drove this customer to purchase “cheap” equipment. The 24/7 operation in Egypt requires sturdy machinery, with a cooling system appropriate for the local climate.

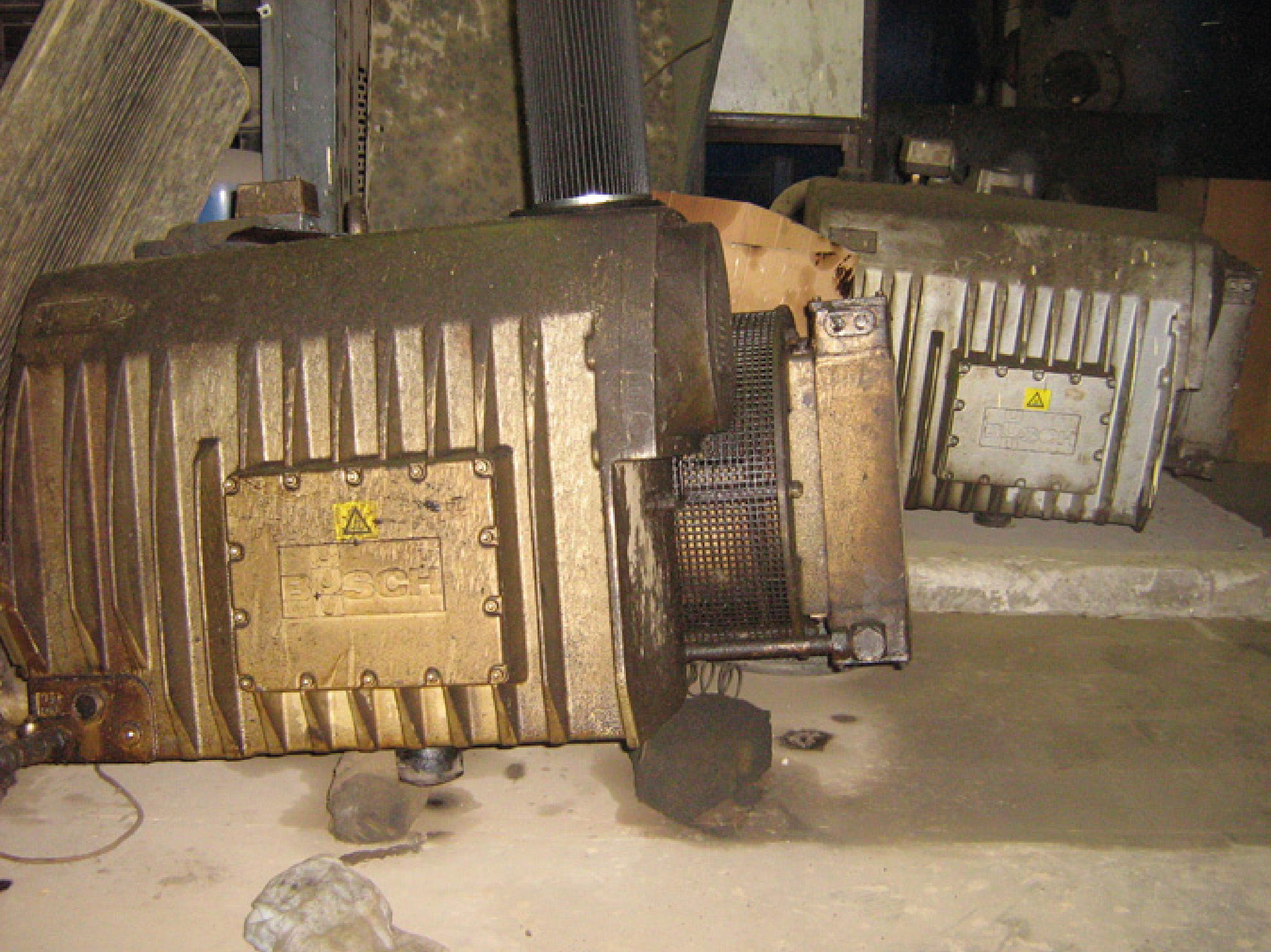

Not a surprise to find the pumps installed before the UVs on the junk pile, see picture on the right. Those machines were trashed out of desperation, the continuous failure of the same caused considerable trouble to the production. Unfortunately, the learning cycle has a price, initial savings turn out to cause huge losses. The life span of non-industrial pumps in glassworks is measured in weeks, the fingers of two hands are enough to count the number. The reasons for Pneumofore, the inventor of single stage rotary vane technology back in the 1920’s, to use vanes made of metal, to offer a complete machine and an efficient and durable solution, are the ones described above and hundreds more.

This is how copies differ from the original. This is why Pneumofore is a healthy, medium sized, same family owned company in its third generation, where the CEOs always had and has a solid mechanical engineering education. We offer solutions and win any Life Cycle Cost race, because our mind is technical before being economical. Picture below shows two UV50 vacuum pumps, soon escorted by a third one, according to the MGM budget 2008.