Rotary Vane Technology

The enduring Rotary Vane design offers a wider range of benefits than other compressor and vacuum pump types, such as screw or liquid ring. Pneumofore has optimized the functionality of the Rotary Vane technology and improved its performance since 1923.

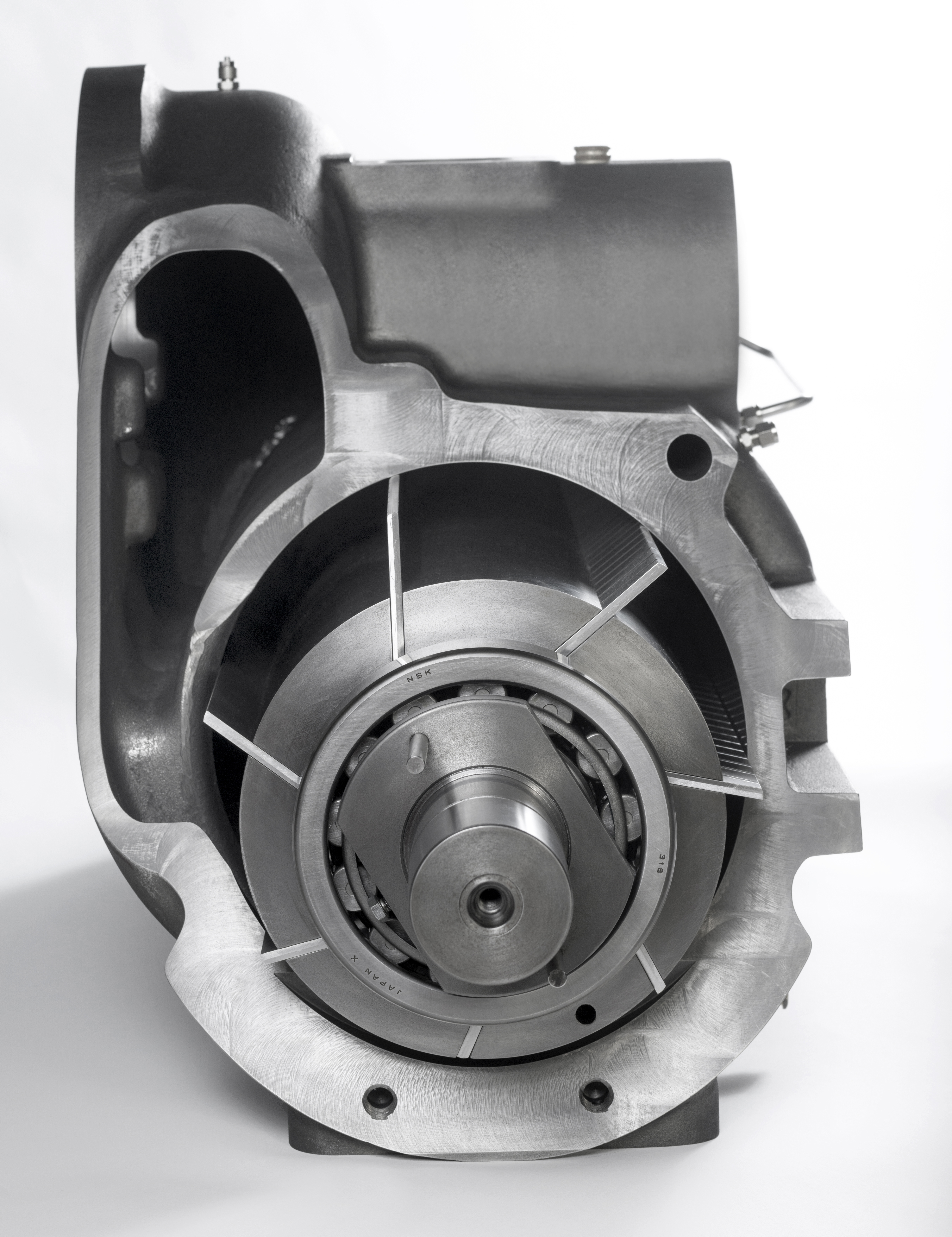

THE AIR-END

The rotary vane air-end is the core of the Pneumofore’s technology: a single piece of extraordinary reliability and durability. The air-end design and its key elements, such as the vanes, bearings and direct drive, are fundamental to meet the criteria for high production performance, long-term operation and low maintenance.

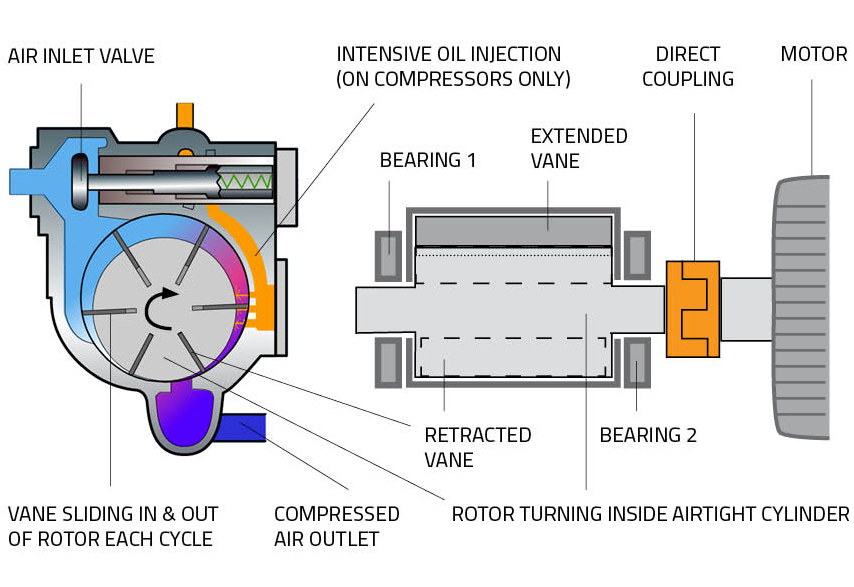

HOW IT WORKS

The Pneumofore rotary vane air-end comes in compressor or vacuum pump versions which slightly differ. The basic principle is the same for both. The air-end consists of several sliding blades set into a rotor which turns on an eccentric axis within a static, air-tight cylinder. When the rotor turns, the centrifugal force causes the blades to slide and extend out of the rotor’s longitudinal grooves. In their extended state, these blades function like vanes that adjust to the cylinder’s shape as they are driven by the rotor.

Incoming air enters the air-end when the pressure-activated air inlet valve, which is the regulating piston, opens. This occurs once designed operating conditions are reached. The air is drawn into the cylinder by the rotating vanes, which enclose space hermetically as they course through the compression area. The air is compressed as the volumes between the vanes are reduced due to the eccentricity of the cylinder wall and the rotor. After maximum compression, the air exits through the outlet. In compressors, the intensive injection of coolant reduces the overall temperature of the compression cycle and ensures copious lubrication. The injected coolant also functions as an active sealant to keep the vanes airtight.

FEATURES & BENEFITS

Simple Design with Few Moving Parts

Sturdy, compact construction, easy to access and maintain, easy replacement of parts, extremely reliable and durable.

Single-Stage Compression

The nature of the design produces sufficient compression in a single stage, resulting in a high compression ratio during a single cycle (about 10:1), as well as better energy efficiency, reduced risk of faults, and reduced maintenance requirements.

Direct Axial Coupling to the Motor

Direct coupling is possible because the high compression ratio permits low rotation speeds, eliminating the need for transmission or gears. Fewer parts means lower energy dissipation and simplified maintenance.

Low Rotation Speed

Lower speed reduces vibration, thus diminishing noise and wear, lowering the temperature and eliminating the need for cement foundations.

Low Cycle Temperature

Lower temperatures reduce wear, coolant consumption, and leakage caused by distension of parts. Less energy is needed for cooling, and the purity of delivered air is enhanced.

Low Maintenance

With fewer parts suffering little wear, single-stage rotary vane units offer cleaner and more reliable operation, significantly reducing maintenance needs.

Air-End Details