The process of polymer degassing at the extruder is necessary to remove all the air and the residual volatile components. But these gasses can be toxic and aggressive and they can damage and compromise the functioning of standard equipment and vacuum pumps. On the contrary, a tailored vacuum system can separate and remove most of the volatile impurities. Pneumofore supplies the rubber industry since 2008 with dedicated vacuum systems for tyre and hose moulding. Quality specifications, remote control and higher vacuum level are some of the features that can be found in the Pneumofore installations worldwide. The most recent systems are running in Mexico, UK and Romania while many other vacuum systems have been running for over a decade in Italy, France, Poland and India. Customers choose Pneumofore for the durability, ease-of-maintenance and trouble-free operation as well as for the high vacuum level that can be reached by the air-cooled UV Series vacuum pumps.

Is there any alternative to PET to preserve, store and transport liquids? PET and other harmful options have a disastrous environmental impact. Does the high percentage of recycling of aluminium cans contribute to slowing down Climate Change?

These are the questions central to the “Aluminium Can…Change?” project. Sponsored by Pneumofore, it is designed to encourage students to seriously reflect upon the environmental impact of consumable goods, including both their full production cycle and packaging. The project, which is currently running with the participation of the students of the Albertina Academy of Fine Arts in Turin (Italy), aims to inspire a new approach toward environmental issues and a deeper understanding of the impact of daily habits.

The inter-disciplinary path of the project ranges from the history of liquid containers to the analysis of aluminium characteristics, through art, visual communication, photography and design with the intention of discovering new shapes and uses, whilst promoting a strong awareness of sustainability and environmental concerns.

The project will culminate in the publication of a multi-lingual book and an exhibition of student works that will be held by the end of 2021 in the Academy’s impressive circular “Rotonda Talucchi” building.

As a leading supplier of high-efficiency and energy-saving vacuum and compressed air systems for the global canmaking industry, Pneumofore enthusiastically supports the “Aluminium Can…Change?” project. The company maintains its ongoing commitment to manufacturing choices which reduce the overall carbon footprint impact.

The project is led by the Sehen Foundation in collaboration with the Albertina Academy and with the participation of the School of Artistic Design for Business and the Polytechnic of Turin.

For more information: www.sehen.org .

In a 15-year comparison, the electricity cost of running a 250 kW compressor exceeds the initial purchasing cost of more than 30 times. This is the average result by considering capex and power consumption cost only, but it can be even more impressive if after-sale maintenance, shut-down time and overhauling costs are added. This was the highlight presented by Pneumofore at Latamcan 2021, one of the major international conferences and the most important technical event for the Latin America metal packaging sector. Hold in Mexico City from September 22 to 24, the event represented a must-attend opportunity for face-to-face meetings in these years of restrictions. At the conference, the CEO of Pneumofore, Rolf Hilfiker, was welcomed as a keynote speaker and pointed out how a clear view over the entire Life Cycle Cost picture is essential before any purchasing decision.

Weck Glaswerk, one of the most historical and renowned glassworks in Germany, is relying since decades on the Rotary Vane technology for the supply of vacuum and compressed air at the IS machines.

In 2017, for the expansion of its production plant in Bonn, the company installed the first Pneumofore UV30 vacuum pump.

This Rotary Vane machine fully met the expectations. The efficient non-stop operation and the ability to independently service the machine reinforced Weck’s faith in Pneumofore.

In fact, the company installed a second Pneumofore UV30 unit, equipped with Variable Speed drive, and commissioned a Pneumofore A400.4 low pressure air compressor for the supply of 3 bar(g).

Owing to the steady running of the Pneumofore machines under full load over the years, Weck Glaswerk was happy to document the results and the confirmed power consumption savings with a video testimonial. With a pure and honest testimonial, Weck is demonstrating the improvements achieved in meeting the demanding German carbon footprint reduction rules.

Specifically designed for gas applications, the innovative Pneumofore KV16 vacuum system can operate in hazardous areas classified Atex Zone 2. Fully customized according to the customer’s specifications, this unit is based on the Pneumofore Rotary Vane technology and provides a flow capacity from 714 to 1.220 m3/h. Equipped with Variable Speed drive, the machine is driven by an Atex-certified motor and its low rotation speed ensures high operational safety standards and minimal maintenance requirements. The sound proof cabinet significantly reduces the noise level while in operation. The unit is air-cooled and ready-to-use for ease of installation. Thanks to its simple geometry and sturdy design, this machine guarantees stable efficiency over time. Along with KV vacuum systems, Pneumofore also manufactures a full range of single- and multi-stage compressors up to 20 bar(g) for gas treatment and processing.

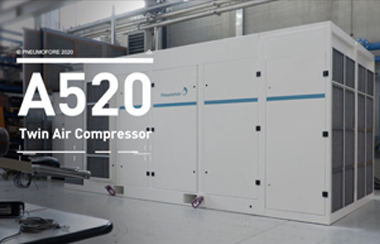

Pneumofore presents the A520 twin air compressor. Specifically designed based on the customer’s requests, this unit is equipped with two Rotary Vane air-ends working at the same time and it delivers between 17.5 to 75 m3/min with a nominal installed power of two-time 200 kW, totally 400 kW. Thanks to its sturdy design, this machine can operate in harsh environments and ensures long-life, stable efficiency over time. Equipped with control and monitoring system of the main brands available on the market, the A520 represents the next generation of Pneumofore compressed air systems.

Pneumofore machines are sold with pay-back calculations. For our customers, the average Return on Investment is 36 months, sometimes even less. With a sharp analysis of the present status and the expected future situation, our engineers estimate the achievable energy savings over years of operation. Catalogue data are not sufficient to effectively compare machinery alternatives. For this reason, clients rightly give rising relevance to guaranteed efficiency values and require quantitative statements on after-sale costs. On these core topics, Pneumofore is well positioned. The picture shows 3 air-cooled vacuum pumps, model UV50 VS, running at Ardagh Glass in Doncaster(UK) since September 2020. Pneumofore agreed on installing this vacuum system with the guarantee of 20% less energy usage than the previous system. At the commissioning made by our technicians, the saving in electrical consumption was measured to be at least 24%. The customer exclaimed: ”Pneumofore is over-performing!”

A new machine is born. Pneumofore engineers met the challenge to design a second gas compression stage from 8 to 14 bar(g). We worked for months to prepare the prototype in order to satisfy the request of a European liquefied natural gas processing company, which had contacted +10 other companies but without any result. The gas processed is mostly CH4. The compressor is Atex certified, assembled as Skid and with FAD flow of 6.000 l/min. After the fine-tuning of pressure and temperature, we have now set the optimal operation limits. This is a completely innovative solution, as we have no knowledge of the existence of any other similar solution, based on the Rotary Vane technology.

An outstanding report about amazing results obtained by the total remake of the vacuum system at the Ball plant located in Milton Keynes, UK.

Having concluded that the original 6 screw vacuum pumps setup was too costly to maintain, the Company considered a vacuum system upgrade. Confronted with an expensive quotation for overhauling, the customer evaluated its total replacement. The time was right also for a complete remake of the pipeline system with the installation of a new vacuum receiver of 10.000 liters, in order to avoid vacuum level fluctuations in production. Pneumofore was contacted, the machine quotation for 3 x UV50 VS90 vacuum pumps was about 220.000 GBP, the required additional pipeline works were quoted for 150.000 GBP, the total amount of 370.000 GBP had to be repaid in savings within 24 months.

The remake of the vacuum piping system, according to Pneumofore specifications, was of central importance. The vacuum pumps alone would not have allowed the impressive short payback. The 6 dated screw pumps were finally replaced in 2019 with the 3 x UV50 VS90. All new pumps were equipped with a Variable Speed drive and interconnection to share the workload and hours. During the start-up the local team was trained to operate the new pumps and now, after about 1 year, the first status analysis was performed in occasion of the yearly ordinary maintenance operations. The monitoring of total power consumption provided precise data, which permitted an accurate calculation of savings. The annual savings of 170.000 GBP in electrical power consumption alone was confirmed. Within the first year also the maintenance cost was reduced by more than 15.000 GBP. The life expectancy of UV pumps is +20 years. In case of continuous running, the overhaul is recommended after 12 years of operation. Hundreds of UV pumps worldwide prove that proper maintenance can stretch the machine life expectancy to +20 years without overhauling, as the performance of the Pneumofore Rotary Vane pumps remains constant in time. With a very cautious estimate of 10 years pump’s life, we estimate that the yearly saving of 185.000 GBP confirms the payback of the new Vacuum System in less than 2 years and it will continue to save electricity and maintenance cost for the total of additional 1.480.000 GBP in the 8 years to come.

Not only the machine investment but the total expense for completely new machines, plus the full remake of the piping system, has yielded the expected Return on Investment period of 24 months.

The most popular Pneumofore product is the UV50 Vacuum Pump. Here are 5 units being prepared for shipping. They will be in operation at a major European hollow glass manufacturing plant. All these pumps are air-cooled, equipped with Variable Speed drive for frequency variation from 30 to 65 Hz. This allows a wide range of capacity from 1.650 to 17.800 m3/h, at any vacuum level setpoint between 50 and 450 mbar(a), [16 to 28,4‘’ Hg vacuum] with constant efficiency. The customer chose Rockwell components for the electrical cabinet. They are all equipped with PLC for remote control by means of the exclusive Pneumofore central vacuum system management device, named VacMan.

Pneumofore flexibility in adapting to special customer requests highlights the competence of our engineering team and sets us apart from our competitors. In the long run, the features of the UV50 pumps which are highly respected by our global users are not necessarily of an electronic nature. Provided the setup of the entire vacuum system is properly dimensioned and fine-tuned, what operators value is the speed and low need of service. The simple and infrequent maintenance requirements notably contribute to the engineering appeal of the UV50, which is the largest and only single stage, air-cooled pump with life expectancy of greater than 20 years.

* cit. Leonardo Da Vinci