Air Compressors for Steel Plants

The environment in a steel plant is uneasy, equipment must be sturdy and durable. There is no space and no time for delicate maintenance operations, but the clear request of trouble-free, reliable and high performance machinery.

Hot Roll is a steel plant for hot rolled and forget parts of different shapes and sizes up to a max. diameter of 450 mm, 170 mm height and 48 kg weight. The materials are various C based metals with variable Mn, Cr, Ni and Mo grades. With the majority of the production sent abroad to European, but also US destinations, this industry represents a demanding, yet relevant customer. The five production lines, partially dedicated to the mass production market like the automotive one, run continuously. Additional processes have been integrated since 1998, like heat treatment and a globular annealing furnace.

The compressed air is key in several movements within the factory, which are executed pneumatically. The ambient air in the production area is more than dusty. The demand for compressed air is large, but the air to compress is inadequate for any compressor. This issue can be solved with large, special inlet air filters. However, Pneumofore engineers are surprised about the longevity of the rotary vane air compressor mod. UR12 from the year 2001, here described. The metal content in the dust is such, that hardly any electronic component lasts. This and more reasons motivate the preference for the standard Pneumofore electro-pneumatic control and power panel.

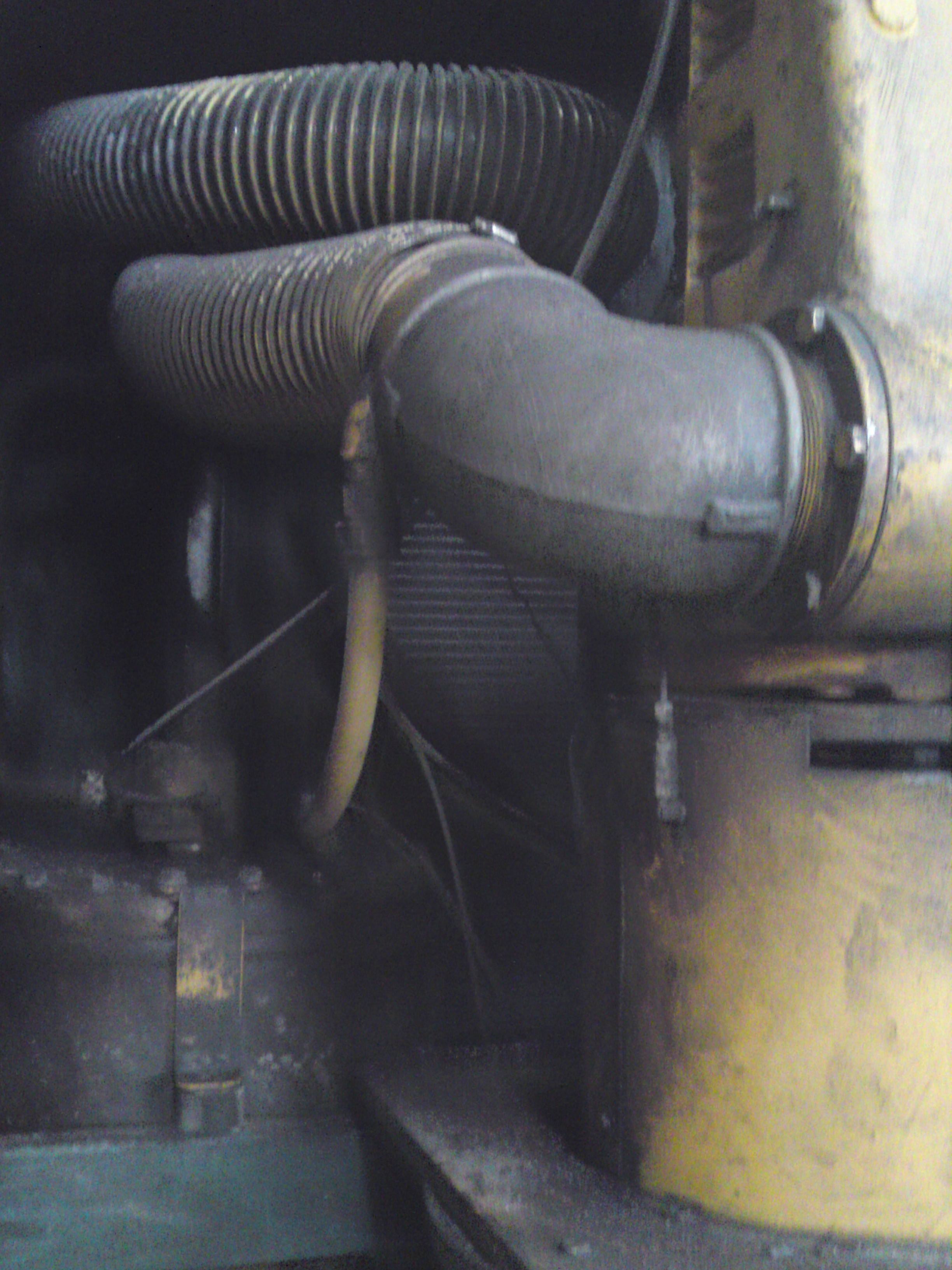

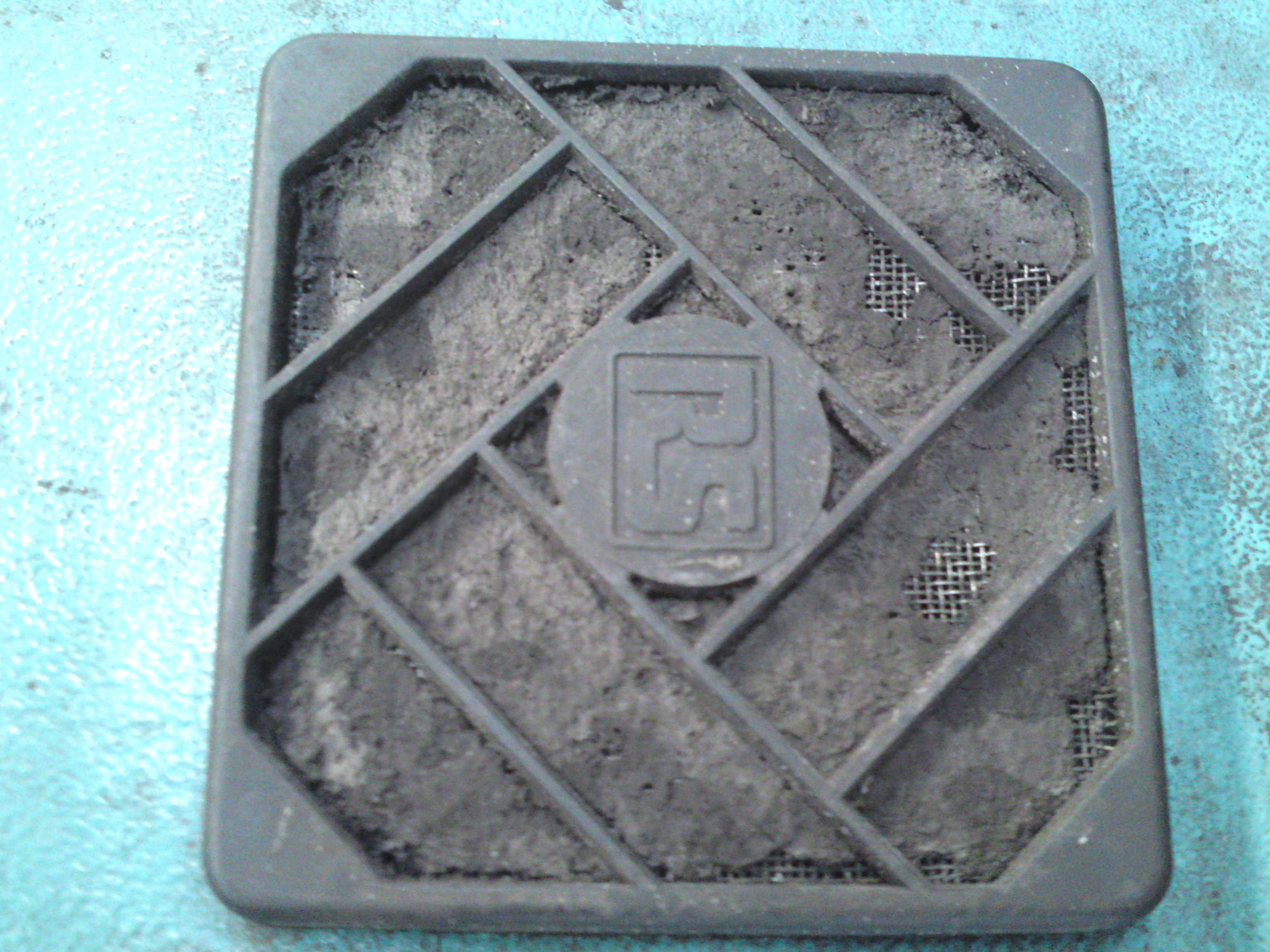

After 10 years of regular maintenance on site, time had come to check the unit allover. The machine showed during the overhaul works remarkable signs of heavy-duty work, that clearly explain the need of a major service. The compressor is quite dirty, the inside is even worse, see picture 1. We pick here few items, which deserve attention, although the environment in a steel plant production area is almost unique. The forced cooling of the control panel is mandatory, as hot forging areas are notably very warm. The filtration of this cooling air is trouble, consequently also the cleanness of the electric contactors, see picture 2 and 3. We noticed how the key components were in order, the air end did not need the replacement; the inside of pipes, coolers, oil receiver were clean. A 3 mm layer of black irondust on the air cooling fan and on the cooler surface influenced the thermo- and fluid-dynamic performance of the cabin- and oil-cooling.

An air compressor running in the production area of a steel plant, three shifts, for ten years, about 40.000 h, air cooled, is a good result. The easy overhaul of the rotary vane air end for the next decade, is even better. The low machine cost over all these years compensates widely the initial high price of reliable and durable quality components; it pays off on the long term. The long maintenance intervals and the fast service, due to ease of maintenance and total accessibility; the air cooling with hot and dusty air; the vertical layout of the machine for minimal space requirement; the direct coupling with low rotation speed; the low temperature of operation with the patented oil injection, these features are typical for Pneumofore compressors. Fortunately, our machines feel comfortable in such steel plant ambient, loud and tough, with extreme work, durability, reliability and high performance expectations.