-

home :404 SORRY, NO PAGE FOUND

home :404 SORRY, NO PAGE FOUND

404 SORRY, NO PAGE FOUND

-

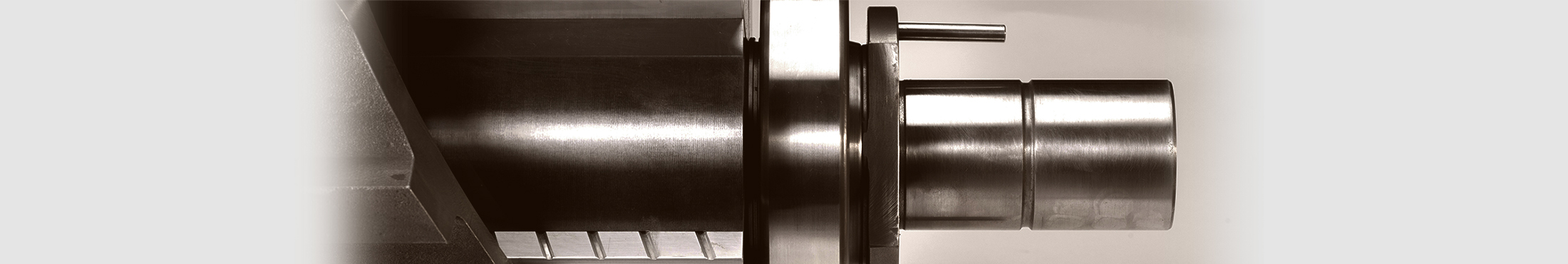

THE ROTARY VANE AIR END BY PNEUMOFORElargest air-cooled vane compressors and pumpsPneumofore leads the market with the largest single-stage rotary vane machines, both as standalone units

THE ROTARY VANE AIR END BY PNEUMOFORElargest air-cooled vane compressors and pumpsPneumofore leads the market with the largest single-stage rotary vane machines, both as standalone units

capable of up to 6,480 m3/h displacement, or in series for any size.simple, reliable & durableDirect coupling means few moving parts, low rotation speed, low temperature. This virtually eliminates repairs

and ensure superior reliability and longevity.low cost of operationLow maintenance, negligible repairs, high energy savings, and high reliability (no production downtime) make this the

least costly long-term option available today.THE ROTARY VANE AIR END

BY PNEUMOFORElargest air-cooled vane

compressors and pumpsPneumofore leads the market with the largest

single-stage rotary vane machines, both as standalone

units capable of up to 6,480 m3/h displacement,

or in series for any size.simple, reliable & durableDirect coupling means few moving parts, low rotation

speed, low temperature. This virtually eliminates

repairs and ensure superior reliability and longevity.low cost of operationLow maintenance, negligible repairs, high

energy savings, and high reliability (no production

downtime) make this the least costly long-term option

available today. -

ROTARY VANE MACHINES BY PNEUMOFORElargest air-cooled vane compressors and pumpsPneumofore leads the market with the largest single-stage rotary vane machines, both as standalone units

ROTARY VANE MACHINES BY PNEUMOFORElargest air-cooled vane compressors and pumpsPneumofore leads the market with the largest single-stage rotary vane machines, both as standalone units

capable of up to 6,480 m3/h displacement, or in series for any size.designed for extremesTested and proven for high performance in desert and tropical climates and available for special requirements

like explosive gas or food safety.high energy savingsAir cooling through vertical layout, direct coupling, and intensive oil injection can result in up to 70% less power

usage than other systems.ROTARY VANE MACHINES

BY PNEUMOFORElargest air-cooled vane compressors

and pumpsPneumofore leads the market with the largest

single-stage rotary vane machines, both as standalone

units capable of up to 6,480 m3/h displacement, or in

series for any size.designed for extremesTested and proven for high performance in desert and

tropical climates and available for special requirements

like explosive gas or food safety.high energy savingsAir cooling through vertical layout, direct coupling, and

intensive oil injection can result in up to 70% less power

usage than other systems. -

PROCESS AIR TECHNOLOGY BY PNEUMOFOREfirst class supportEach unit come with integration engineering and a 5-year warranty. Extraordinary and regular service by

PROCESS AIR TECHNOLOGY BY PNEUMOFOREfirst class supportEach unit come with integration engineering and a 5-year warranty. Extraordinary and regular service by

Pneumofore-certified professionals is available worldwide.low cost of operationLow maintenance, negligible repairs, high energy savings, and high reliability (no production downtime) make this the

least costly long-term option available today.designed for extremesTested and proven for high performance in desert and tropical climates and available for special requirements

like explosive gas or food safety.PROCESS AIR TECHNOLOGY

BY PNEUMOFOREfirst class supportEach unit come with integration engineering and a

5-year warranty. Extraordinary and regular service by

Pneumofore-certified professionals is available

worldwide.low cost of operationLow maintenance, negligible repairs, high energy

savings, and high reliability (no production downtime)

make this the least costly long-term option

available today.designed for extremesTested and proven for high performance in desert and

tropical climates and available for special requirements

like explosive gas or food safety.